CTOD Testing Services by Qualitest Canada as per International Codes and Standards

Qualitest Canada provides specialized CTOD (Crack Tip Opening Displacement) Testing in Edmonton, Canada, delivering fracture-toughness data that complies with major international codes and standards used worldwide. Our ISO/IEC 17025–accredited laboratories and fracture-mechanics engineers support weld qualification, Engineering Critical Assessments (ECA), and fitness-for-service across offshore, pipeline, structural, marine, and pressure-equipment projects.

We proudly serve clients across Canada, including Toronto, Halifax, Nisku, Calgary, Red Deer, Grande Prairie, Fort McMurray, Regina, Saskatoon, Vancouver, Surrey, Burnaby, Kamloops, Kelowna, Mississauga, Hamilton, Sarnia, Ottawa, London, Windsor, and Sudbury.

Understanding CTOD (Global Context)

CTOD measures the opening displacement at a crack tip immediately before fracture and is a primary input to fracture-toughness-based acceptance criteria and ECA/FAD methods. Internationally, CTOD is executed mainly per BS EN ISO 15653 (welds) and ASTM E1820 (J/CTOD), with ISO 12135 as a unified method reference for metallic materials.

International Codes & Standards that Require / Reference CTOD

Pipelines & Onshore Transmission

- API 1104 – Welding of Pipelines and Related Facilities (Annex fracture-toughness route using CTOD for weld/HAZ).

- CSA Z662 – Oil & Gas Pipeline Systems (Annex K/J ECA with CTOD inputs for flaw acceptance).

- DNV-ST-F101 – Submarine Pipeline Systems (CTOD for girth-weld qualification and strain-based design).

- ISO 3183 / API 5L – Line Pipe (project specs often call CTOD for higher-grade steels and weld procedures).

- ISO 15156 / NACE MR0175 (sour service; CTOD often specified in project-specific weld qualifications).

- Offshore & Structural (Fixed/Floating)

- BS EN ISO 15653 – Fracture-toughness testing of welds (procedural basis for CTOD on weld metal/HAZ).

- ISO 12135 – Unified method for fracture toughness of metallic materials (methodological reference).

- EN 10225 – Weldable structural steels for fixed offshore structures (CTOD at design temperature for weld/HAZ).

- NORSOK M-601 – Welding & inspection of piping and equipment (CTOD for critical joints/materials).

- BS 7910 – Flaw assessment (ECA) (requires CTOD/J as toughness inputs for FAD-based acceptance).

Marine & Classification Societies

- DNV (RU/Offshore), ABS, Lloyd’s Register – class rules and offshore standards frequently require CTOD on critical welded joints (arctic/ice-class, dynamic loads, low-temperature service), executed per ISO 15653 / ASTM E1820.

Pressure Equipment, Refineries & Power

- API 579-1 / ASME FFS-1 – Fitness-for-Service (Level-3 fracture assessments accept CTOD/J inputs).

- ASME BPVC VIII-3 – High-pressure vessels (fracture-mechanics design routes may use CTOD/J data).

Project Specifications / EPC Requirements – Many operators mandate CTOD on procedure quals for low-temp or high-constraint weldments.

Need help mapping your project spec?

We routinely cross-walk owner requirements to test plans aligned with ISO 15653 / ASTM E1820 and the governing code.

Why Qualitest Canada

- ISO/IEC 17025–accredited facilities

- Servo-hydraulic frames with high-resolution CMOD/COD acquisition.

- Expertise across API 1104, CSA Z662, CSA W59 Annex U, ISO 15653, ASTM E1820, EN 10225, DNV-ST-F101, BS 7910.

- Comprehensive reports: load–CMOD curves, δ (CTOD) values (δc, δu, δm), fracture photos, location mapping, and clear code-compliance statements.

Our CTOD Testing Capabilities

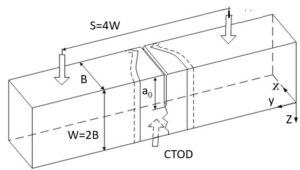

- Specimens: SENB B×2B (preferred) or B×B; extraction at representative positions (e.g., 12 o’clock for pipelines), oriented parallel to pipe axis when applicable.

- Pre-cracking: Per ISO 15653 / ASTM E1820; fatigue extension and crack-front straightness controls.

- Environment: Ambient to sub-zero (min design/service temperature).

- Acquisition: Synchronized load + CMOD; surface CMOD for shallow-crack analysis where required.

- Data Reduction: δ₅ / δc / δu / δm and J-integral as specified; ECA-ready datasets for FAD/BS 7910 / DNV methods.

Benefits of CTOD (Global Projects)

- Enables toughness-based acceptance of weld imperfections via ECA/FAD.

- Demonstrates fitness-for-service in low-temperature, dynamic, or high-constraint conditions.

- Supports WPS/PQR approvals across multiple codes and reduces rework/repairs.

- Provides validated inputs for integrity assessments and FEA.

Industries We Serve

- Pipelines & Terminals (onshore/offshore)

- Offshore Oil & Gas / Subsea

- Structural & Heavy Fabrication

- Marine / Classification

- Refining, Petrochem & Power

- Engineering Design & Failure Analysis

Other Qualitest Services

- Charpy Impact & Fracture Toughness (K_IC / J)

- WPS/PQR & Welder Certification (API 1104 / CSA Z662 / CSA W59 / EN 10225)

- Metallography & Hardness Mapping

- Chemical Analysis (OES, ICP-OES)

- NDT (UT, MT, PT, RT, AE, GPR)

- Concrete, Asphalt & Aggregate Testing

- Geotechnical & Environmental Investigations

Contact Us

📧 Email: admin@qualitests.com

- Ontario Office: 5, 760 Laurentian Dr, Burlington, ON L7N 3V6 | ☎ (647) 464-9480

- Alberta (Nisku): 702 – 23 Ave, Nisku, AB T9E 7Y6 | ☎ (780) 851-2020

- Alberta (Calgary): 320A – 65 Ave SE, Calgary, AB T2H 0R8 | ☎ (587) 747-3787

- British Columbia: 112, 13085 115 Ave, Surrey, BC V3R 0C3 | ☎ (778) 381-7376

Accredited to ISO/IEC 17025:2017 (Nisku, AB & Surrey, BC)