Ultrasonic Testing for Railroad welds in Ontario

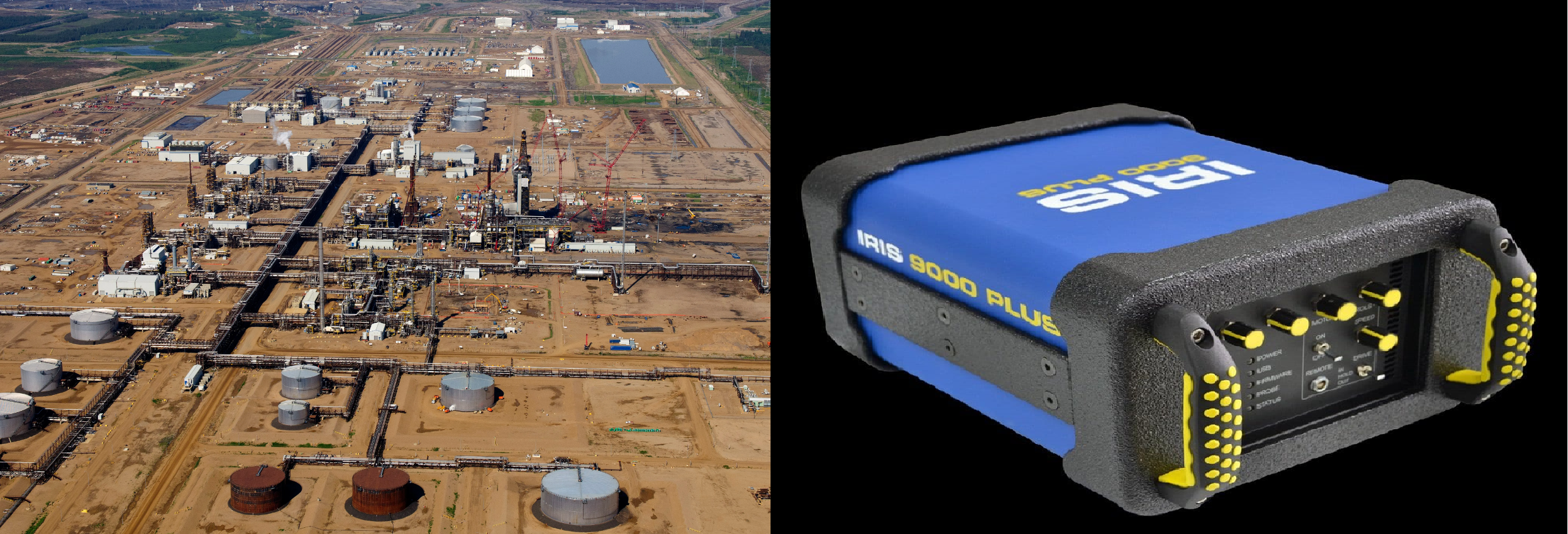

Qualitest Canada provides Ultrasonic Testing for railroad welds in Ontario which includes Flash butt welds and Thermit Welds. Qualitest can send its inspectors with the fully loaded gears to any corners of Canada including Vancouver, Edmonton, Manitoba, Toronto, Hamilton, Mississauga, Sarnia, Calgary, Fort McMurray, Peace River, Cold Lake, Grande Prairie, Conklin, Surrey, Langley, Richmond, Delta, Burnaby, Victoria, Kitimat, Terrace, Fort St. John, Dawson Creek, Kelowna, Kamloops, Red Deer, Regina, Saskatoon, Lloydminster etc from the nearest Qualitest’s office located.

The strength and reliability of rails during their operation is crucial for the railway industry. This is connected to the fact that the development of defects and violations of the strength characteristics of the rails may lead to their breaking or even to railway crashes. Long-term operation of rails showed which defects were mainly developing and, of course, this may seriously affect the safety of the railway transportation. Qualitest Canada provides top notch in-service non-destructive rail UT testing services with a short notice. Our approach is very quicker and through as the maintenance teams in railway industry are facing challenges in maximizing the efficiency and life expectancy of their assets but without sacrificing safety and reliability.

Railway tracks are inspected by ultrasonic high frequency waves. Usually ultrasonic rail flaw detector uses the ultrasonic waves with a frequency of 2 to 5 MHz to inspect rails. The defects in rails have different nature: direction of development, manufacturing defects, operational defects.

As Qualitest Canada’s Inspectors are always cautious with the complicated design of the rails, so they use the calibration blocks made from the similar configuration to make sure the work can be done correctly. Ideally, our inspectors do practice and calibrate the equipment with the custom made calibration blocks before performing the actual work at the site. Our highly skilled and knowledgeable engineers and certified inspectors are using wide range of equipment are capable to solve different NDT problems. We perform the NDE/NDT during new construction of the railroads or in service in accordance with the client’s requirements.

With this advanced on-site reporting there is no more waiting days for a report, decisions based on weld condition can be made in less than a few hours. Qualitest can handle any size of the Ultrasonic Testing project within Canada and beyond.

Contact us admin@qualitests.com today to get a quote.