Tube inspection with IRIS (Internal Rotary Inspection System) Technology

Qualitest Canada performs Tube inspection with IRIS (Internal Rotary Inspection System) Technology through its highly qualified Inspectors. Qualitest Canada’s Inspectors perform advanced tube inspection with IRIS technology throughout Canada including Toronto, Mississauga, Hamilton, Sarnia, Milton, St. Catharines, Ottawa, Brampton, London, Markham, Vaughan, Kitchener, Windsor, Vancouver, Surrey, Langley, Richmond, Delta, Burnaby, Victoria, Kitimat, Dawson Creek, Kelowna, Kamloops, Edmonton, Calgary, Red Deer, Peace River, Grande Prairie, Fort McMurray, Regina and Saskatoon.

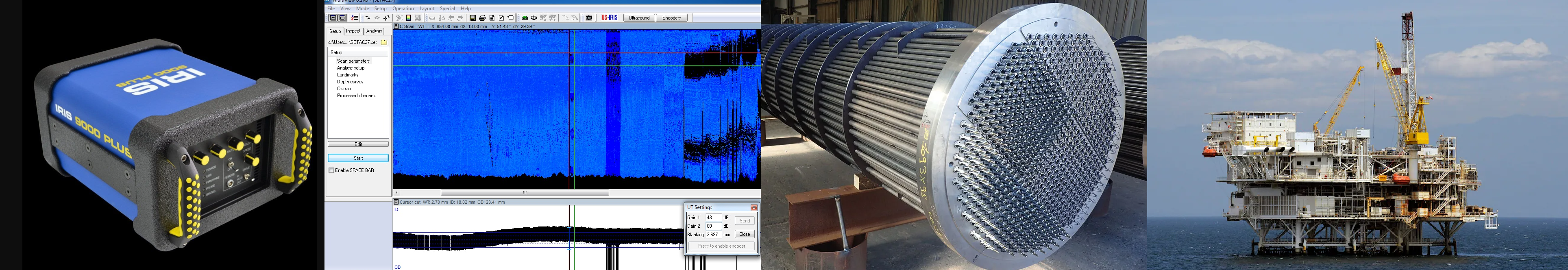

IRIS (Internal Rotary Inspection System)

IRIS (Internal Rotary Inspection System) is an ultrasonic method used for the non-destructive testing of tubes and pipes. The maintenance team in many processing facilities in the utility, oil, gas and power generation industries is facing challenges in maximizing the efficiency and life expectancy of their assets but without sacrificing safety and reliability. Therefore accurate inspection of vital components such as tubes and pipes is crucial to ensuring the integrity of the plant.

IRIS (Internal Rotary Inspection System) technology can detect corrosion, pitting and wall loss and is most commonly used for tube inspection in boilers, heat exchangers, air coolers and feed water heaters. It is particularly versatile as it is suitable for both ferrous and non-ferrous materials, and IRIS can be used on a wide range of tube diameters and wall thicknesses. An IRIS probe is inserted into a tube flooded with water. The probe is fitted with a transducer that generates an ultrasonic pulse along a path parallel to the axis of the tube. A rotating mirror directs the ultrasonic pulse into the tube wall. The mirror is driven by a small turbine that is rotated by the pressure of water pumped into the tube.

The ultrasound pulses are reflected by the inner-diameter (ID) wall and outer-diameter (OD) wall of the tube and the time of flight difference between the two diameters is used to calculate the wall’s thickness. As the IRIS probe is pulled, the spinning motion of the mirror results in a helical scan path ensuring full coverage of the tube.

Benefits of using IRIS include:

- Suitability for ferrous and non-ferrous pipes and tubes.

- Detection of corrosion, pitting and thickness loss

- Accurate wall thickness measurements

- Sensitivity to both internal and external defects

- Defect position can be located in relation to tube length

- 100% coverage of the tubes

- Results data storage

Flexibility as a back-up to remote field, magnetic flux leakage and eddy current inspections. Our NDT inspectors have years of experience using IRIS and they can provide you with an accurate assessment of the condition of your assets and Total Quality Assurance.

Once the field inspection is complete, an on-site final report is immediately generated. This report consists of a detailed description of the inspection findings, a summary of the test results, tube sheet maps; colour coded by percentage loss/remaining and damage type, side views of the exchanger indicating percentage loss/remaining, detailed information on each tube inspected, along with screen captures of the typical indications found. In addition, supplemental tube sheet maps can be generated for tube plugging or selective re-tubing.

With this advanced on-site reporting there is no more waiting days for a report, decisions based on tube condition can be made in less than an hour. Qualitest can handle any size of the tube inspection project within Canada and internationally.

Contact us admin@qualitests.com today to get a quote.