MFL Tank Inspection Services in Kitimat

Qualitest Canada provides MFL Tank Inspection services in Kitimat and all over Canada including Vancouver, Surrey, Langley, Richmond, Delta, Burnaby, Victoria, Kitimat, Dawson Creek, Kelowna, Kamloops, Edmonton, Calgary, Red Deer, Peace River, Grande Prairie, Fort McMurray, Regina, Saskatoon, Montreal, Toronto, etc…

Qualitest Canada provides the top notch technical and testing solution to the Tank Floor Inspection projects. Our highly experienced technicians will perform the floor scanning and issue a detailed scan report which will be easy to understand by any individuals knows about the tanks.

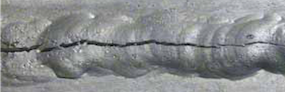

Tank floor MFL scanning is a non-destructive testing method that generates a more thorough and complete inspection of the storage tank floors and walls. A strong magnetic field is used to detect pitting and corrosion in carbon plates on both top and bottom surfaces. This magnetic field is created by strong magnets in close proximity to the carbon steel floors. The magnetic field leaks from the steel where there is pitting or corrosion and a sensor alerts the technician to pay more attention to those locations.

The scanner is dragged over the entire surface of the floor, and areas of concern are verified with ultra sound to obtain wall loss readings. Technicians interpret the scanner display to identify damaged areas and in some cases, estimate the amount of metal loss. Thickness losses detected by ultrasound are reported and mapped in a CAD rendering of the floor.

Advantages

- Thorough inspection of floors in a short period of time.

- Reliable and economical results.

- Access to only one side of tank floor is needed.

- Can scan through most coatings.

- Cost effective comparatively to any other NDT methods.

- Fast method for inspecting large areas.

- Minimal set-up time.

Limitations

- UT (Ultrasonic Testing) is required to verify wall loss of defects.

- Does not decipher which side the wall loss is on.

- Inspection access is limited to areas without components which are close or attached to the floor.

- Tank Floor condition is vital to the integrity of inspection. Scales build up and debris will prevent accurate readings.

- Tank floors must be freshly cleaned and free of all debris.

- Not a quantitative technique for identifying remaining wall thickness.