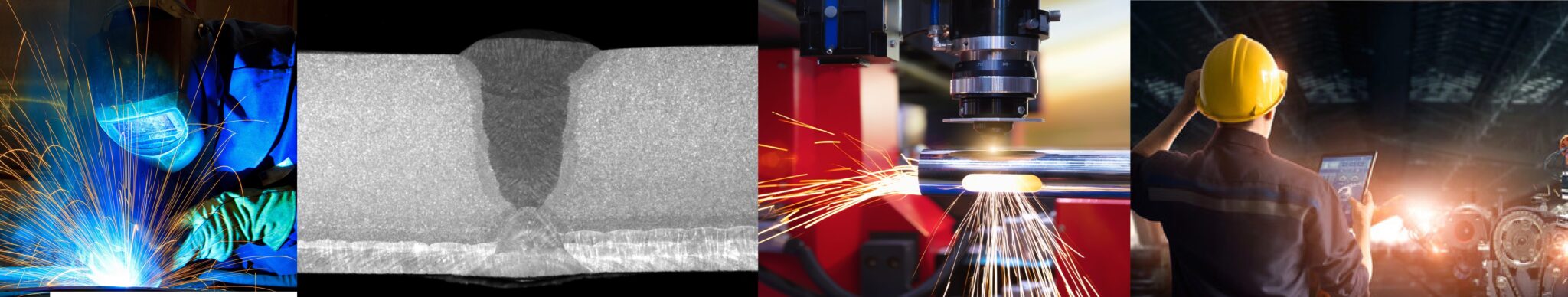

Structural Steel Inspection Surrey BC

Qualitest Canada provides Structural Steel Inspection Surrey BC through it’s highly qualified CWB Level 2 / Level 3 inspectors. The service area includes Surrey, Vancouver, Langley, Richmond, Delta, Burnaby, Victoria, Kitimat, Dawson Creek, Kelowna, Kamloops, Edmonton, Calgary, Red Deer, Peace River, Grande Prairie, Fort McMurray, Regina, Saskatoon etc…

Qualitest Canada’s inspectors have completed structural steel inspection projects in the past including industrial, institutional and commercial sectors. We take care of your structural steel inspection at any stage you need our service. Our inspectors will visit to your project site and perform the steel structural inspection as per the project requirements.

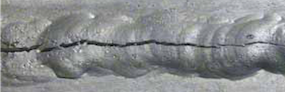

We can provide full range structural steel inspections including visual weld inspection, magnetic particle testing, ultrasonic weld testing, lamination scans, hardness testing and bolt torque testing at the fabrication shop or in the field at the job site. In the past, we have performed full Quality Control inspection programs on offshore drilling platforms and onshore large structural steel projects such the installation of huge structural steel components at various commercial and industrial projects in lower mainland, BC. As we have many years in the structural steel inspection and testing business, we guarantee you with the experience and knowledge you are looking for. We offer a “One-Stop” testing and Inspection service that is second to none.

- Reviewing the blue prints and IFC drawings

- Bolt Tension Verification

- Column verification for verticality (plumbness)

- Verification of Column to beam connections

- Joists and bridges verification

- Metal deck installation inspection

- Rebar inspection

- Field Erection Welding Inspection and Testing

- Interpreting Applicable Codes and Standards

- Non-Destructive Testing

- Verification of Welders and Welding operators

- Verification of Welding Procedures and WPDS

- Fabrication Shop Welding Inspection and Testing

Contact us admin@qualitests.com today to get a quote.

Alberta: 702 – 23rd Ave Nisku, AB, T9E 7Y6, Canada, (780) 851-2020

BC: 112, 13085 115Ave, Surrey, BC V3R 0C3, Canada, (778) 381-7376