CTOD Testing as per CSA Z662 in Toronto Canada

Qualitest Canada provides specialized CTOD Testing as per CSA Z662 in Toronto Canada for pipeline steels and girth-welds. Our ISO/IEC 17025–accredited labs and fracture-mechanics engineers deliver precise CTOD data to support pipeline weld qualification, engineering critical assessments (ECA), and fitness-for-service.

We proudly serve clients across Canada, including Toronto, Halifax, Nisku, Calgary, Red Deer, Grande Prairie, Fort McMurray, Regina, Saskatoon, Vancouver, Surrey, Burnaby, Kamloops, Kelowna, Mississauga, Hamilton, Sarnia, Ottawa, London, Windsor, and Sudbury.

Understanding CTOD for Pipelines (CSA Z662)

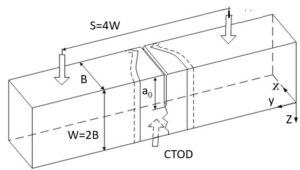

CTOD measures the opening displacement at a crack tip immediately prior to fracture and is used in CSA Z662 to characterize fracture toughness of pipeline steels and weldments, especially at low temperatures and under pipeline service loading. For pipeline girth-weld assessments, CTOD testing follows ASTM E1820 or ISO 15653, with specimens taken from the 12 o’clock position and oriented parallel to the pipe axis. Shallow-crack geometry is permitted with the E1820 equations applied to surface CMOD measurements.

Pre-cracking and temperature: Typical programs test at the minimum design temperature; pre-cracking must meet E1820 criteria (e.g., extend by ≥ 1.3 mm or ao/2, whichever is less) with crack-front straightness controls. CSA Z662 uses the minimum of twelve CTOD values for subsequent acceptance calculations.

ECA in CSA Z662 (Annex J / Annex K)

When weld indications exceed standard workmanship limits, CSA Z662 Annex J allows an Engineering Critical Assessment (ECA) to determine tolerable flaw sizes based on measured toughness (CTOD) and real service stresses. Annex K provides fracture-mechanics-based acceptance options (e.g., classic CTOD design curve or Failure Assessment Diagram) that companies may adopt for construction or specific cases.

Why Qualitest Canada

- ISO/IEC 17025–accredited fracture-mechanics facilities with sub-zero temperature control (–100 °C to +25 °C).

- Servo-hydraulic CTOD frames with high-resolution clip-on COD/CMOD gauges.

- CSA Z662 / BS 7448 / ASTM E1820 expertise for pipelines, girth-welds, HAZ, and line-pipe steels.

- Comprehensive reporting: load–CMOD plots, δ (CTOD) values, fracture photos, and code-specific compliance notes.

(E1820/15653 applicability to shallow cracks and pipeline orientations per CSA Z662 commentary.)

Our CTOD Testing Capabilities

- Specimens: SENB B×2B (preferred) or B×B; specimens from 12 o’clock, oriented parallel to pipe axis.

- Pre-crack: Per E1820; extend ≥ 1.3 mm or ao/2; control crack-front straightness.

- Environment: Ambient to sub-zero per project spec (e.g., minimum design temperature).

- Acquisition: Load + CMOD synchronized; surface CMOD for shallow-crack analysis.

- Data reduction: δ₅ / δc and J-integral as required; minimum of 12 CTOD values used for acceptance calculations.

Benefits for Pipeline Projects (CSA Z662)

- Qualifies pipeline weld & HAZ toughness for construction approval and fitness-for-service.

- Supports WPS/PQR development and verification under pipeline service conditions.

- Enables ECA-based acceptance of weld imperfections to minimize unnecessary repairs.

- Reduces risk of brittle fracture in cold service; provides inputs for structural integrity/FEA.

Industries We Serve

- Pipeline construction and transmission, oil & gas gathering and transmission systems.

- Offshore/subsea pipeline projects, pressure-piping and process facilities.

- Engineering design & failure-analysis organizations.

Other Qualitest Services

- Charpy Impact & Fracture Toughness (K_IC/J)

- WPS/PQR & Welder Certification (CSA W47.1/W59/Z662)

- Metallography & Hardness Mapping

- Chemical Analysis (OES, ICP-OES)

- NDT (UT, MT, PT, RT, AE, GPR)

- Concrete, Asphalt & Aggregate Testing

- Geotechnical & Environmental Investigations

Contact Us

📧 Email: admin@qualitests.com

- Ontario Office: 5, 760 Laurentian Dr, Burlington, ON L7N 3V6 | ☎ (647) 464-9480

- Alberta Office (Nisku): 702 – 23 Ave, Nisku, AB T9E 7Y6 | ☎ (780) 851-2020

- Alberta Office (Calgary): Calgary, AB T2G-3K6 | ☎ (587) 747-3787

- British Columbia Office: 112, 13085 115 Ave, Surrey, BC V3R 0C3 | ☎ (778) 381-7376