CTOD Testing as per API 1104 in Edmonton Canada

Qualitest Canada provides specialized CTOD Testing as per API Standard 1104 in Edmonton Canada ensuring full compliance with API 1104: Welding of Pipelines and Related Facilities, including Annex A.3.4.3 Fracture-Toughness Testing. Our ISO/IEC 17025-accredited laboratories and experienced fracture-mechanics engineers deliver precise and reliable CTOD results for pipeline weld qualification, engineering critical assessments (ECA), and fitness-for-service evaluations across Canada.

Our ISO/IEC 17025–accredited laboratories and experienced fracture-mechanics engineers deliver precise CTOD data supporting pipeline weld procedure qualification, engineering critical assessments (ECA), and fitness-for-service evaluations.

We proudly serve clients across Canada — including Toronto, Halifax, Nisku, Calgary, Red Deer, Grande Prairie, Fort McMurray, Regina, Saskatoon, Vancouver, Surrey, Burnaby, Kamloops, Kelowna, Mississauga, Hamilton, Sarnia, Ottawa, London, Windsor, and Sudbury — as well as international pipeline operators and EPC firms.

Understanding CTOD Testing per API 1104

- CTOD testing measures the fracture-toughness and crack-propagation resistance of weld metal and heat-affected zones (HAZ) in pipeline steels.

- Under API 1104 Annex A.3.4.3, each welding procedure requires CTOD tests on both the weld metal and the HAZ, using at least three valid specimens per location — typically at the 12 o’clock, 3 o’clock (or 9 o’clock), and 6 o’clock positions on the test weld.

- Specimens are oriented parallel to the pipe axis (through-thickness crack direction) and tested at or below the minimum design temperature.

- API 1104 specifies that BS EN ISO 15653 criteria be applied for geometry and crack-front straightness, with valid δ-values (δc, δu, or δm) reported per ISO definitions

CTOD Specimen Orientation and Preparation

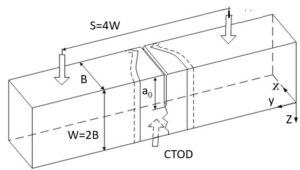

- Specimen geometry: Preferred B × 2B (single-edge notched bend SENB) configuration

- Orientation: Length parallel to pipe axis, crack tip through thickness

- Weld metal tests: Notch and fatigue crack tip located centrally in the weld

- HAZ tests: Pre-cracks aimed at coarse-grain HAZ within the central 70 % of thickness

- Minimum valid CTOD: 0.002 in (0.05 mm) for acceptance of procedure qualification

Applicable Codes and Standards

- API Standard 1104 – Welding of Pipelines and Related Facilities (Annex A.3.4.3 Fracture-Toughness Testing)

- BS EN ISO 15653 – Fracture-Toughness Testing of Welds (CTOD Method)

- ASTM E1820 / E1290 – J-Integral and CTOD Measurement Methods

- CSA Z662 Annex K – Correlative guidance for FAD/ECA assessment (using API 1104 formulation)

Why Choose Qualitest Canada

- ISO/IEC 17025–accredited facilities with sub-zero testing capability (–100 °C to +25 °C)

- Servo-hydraulic CTOD frames with high-resolution clip-on COD/CMOD gauges

- Expertise in API 1104, BS EN ISO 15653, and ASTM E1820 fracture-mechanics methods

- Comprehensive reporting including load–CMOD curves, fracture photographs, and δ value classification

Our CTOD Testing Capabilities

- Specimens: B × 2B or B × B SENB; extracted from 12 o’clock position

- Pre-crack: Fatigue extension ≥ 1.3 mm or ao/2; crack-front straightness per BS EN ISO 15653

- Temperature: At or below minimum design temperature

- Measurement: Synchronized load and CMOD acquisition

- Reporting: δc, δu, or δm values with fracture surface records and photographs

Benefits of CTOD Testing per API 1104

- Ensures fracture-toughness qualification of pipeline weld metal and HAZ

- Supports WPS/PQR approvals and fitness-for-purpose evaluations

- Provides data for ECA and FAD analysis of imperfections (A.5.1.2 – Options 1 & 2)

- Minimizes repairs by allowing toughness-based acceptance criteria

- Enhances reliability in low-temperature and high-stress pipeline service

Industries We Serve

- Pipeline Construction and Transmission

- Oil & Gas and Energy Infrastructure

- Offshore and Subsea Pipeline Projects

- Pressure-Piping and Process Facilities

- Engineering Design and Failure-Analysis Consultancies

Other Qualitest Services

- Charpy Impact & Fracture Toughness Testing (K_IC / J)

- WPS/PQR Qualification & Welder Certification (API 1104 / CSA Z662)

- Metallography & Hardness Mapping

- Chemical Analysis (OES, ICP-OES)

- NDT (UT, MT, PT, RT, AE, GPR)

- Concrete, Asphalt & Aggregate Testing

- Geotechnical & Environmental Investigations

Contact Us

📧 Email: admin@qualitests.com

- Ontario Office: 5, 760 Laurentian Dr, Burlington, ON L7N 3V6 | ☎ (647) 464-9480

- Alberta Office (Nisku): 702 – 23 Ave, Nisku, AB T9E 7Y6 | ☎ (780) 851-2020

- Alberta Office (Calgary): Calgary, AB T2G-3K6 | ☎ (587) 747-3787

- British Columbia Office: 112, 13085 115 Ave, Surrey, BC V3R 0C3 | ☎ (778) 381-7376