Slow-Bend Test of Rail Welds in accordance with AREMA and AWS standards

Qualitest Canada. performs 4-point Slow-Bend Test of Rail Welds in accordance with AREMA and AWS standards throughout Canada with its highly experienced engineers and technicians. Our service area covers almost every major city and town in Canada, including Mississauga, Hamilton, Sarnia, Milton, St. Catharines, Ottawa, Brampton, Sudbury, London, Markham, Vaughan, Kitchener, Windsor, Vancouver, Surrey, Langley, Richmond, Delta, Burnaby, Victoria, Kitimat, Dawson Creek, Kelowna, Kamloops, Edmonton, Calgary, Red Deer, Peace River, Grande Prairie, Fort McMurray, Regina, and Saskatoon.

Introduction to Rail Weld Testing

At Qualitest Canada Ltd., we understand the critical importance of rail weld testing for ensuring the safety and durability of railway tracks. The AREMA (American Railway Engineering and Maintenance-of-Way Association) and AWS (American Welding Society) standards provide essential guidelines for the slow-bend test, which is crucial for evaluating the strength of rail welds. This test helps identify any weaknesses that could lead to track failures, ensuring that rails are safe for use.

Slow-Bend Test of Rail Welds

Importance of Slow-Bend Test

The slow-bend test is a vital procedure in maintaining railway safety. It replicates real-world conditions to test the weld’s integrity under stress. By applying a controlled force, the test identifies potential weak points, ensuring that the rail can endure daily operational stresses.

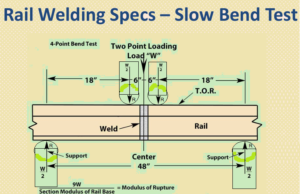

Setting Up the 4-Point Test

Setting up the 4-point test requires precision and strict adherence to standards. Here is a step-by-step guide to ensure accurate results:

Prepare the Rail Sample

Cut the rail sample to the specified length: Ensure the rail sample meets the required dimensions according to AREMA and AWS guidelines.

Ensure the sample is free from defects and impurities: Inspect the sample to remove any surface contaminants or imperfections that could affect the test results.

Align the Test Equipment

Position the rail sample in the testing machine: Secure the sample firmly in place to prevent movement during the test.

Align the supports and loading points according to AREMA and AWS specifications: Proper alignment is crucial for the accuracy of the test. The supports should be positioned symmetrically at the specified distance apart, and the loading points should be equidistant from the supports.

Apply the Load

Gradually apply the load to the rail sample: Increase the load slowly and steadily to avoid sudden impacts that could skew the results.

Monitor the force and deformation closely: Use precise instrumentation to measure the force applied and the resulting deformation of the rail sample.

Record the Results

Document the load and displacement at failure: Record the maximum load the sample withstands and the corresponding displacement at the point of failure.

Analyze the data to determine the weld’s strength: Evaluate the results to assess the weld’s performance and identify any potential issues.

Benefits of Adhering to Standards

Adhering to AREMA and AWS standards ensures consistency and reliability in testing. These standards provide a uniform method for evaluating rail welds, making it easier to compare results across different samples and conditions. This uniformity is crucial for maintaining safety across the railway network.

Common Issues and Solutions

During the slow-bend test, several issues may arise. Here are some common problems and their solutions:

Misalignment of Sample: Ensure the sample is correctly positioned and aligned before applying the load. Double-check the alignment to avoid inaccurate results.

Inaccurate Load Application: Regularly calibrate the testing machine to maintain accuracy. Use properly maintained equipment to ensure the load is applied consistently.

Data Recording Errors: Use reliable data acquisition systems to capture precise measurements. Verify the data recording process to avoid errors in the results.

Conclusion

At Qualitest Canada., we are dedicated to ensuring the highest standards in rail weld testing. The 4-point set-up for the AREMA and AWS slow-bend test is essential for evaluating rail welds. By following these guidelines and maintaining precision, we help railway companies ensure the safety and durability of their tracks. Regular testing and adherence to standards are key to preventing track failures and ensuring smooth operations.

Other Services by Qualitest Canada

Qualitest Canada also provides world-class engineering services in Canada, focusing on:

- Concrete Scanning with Ultrasonic Pulsed Echo

- Utility Locating

- HDPE Burst Test

- Welding Engineering

- Geotechnical Investigation

- Environmental Site Assessment (ESA Phase I, II, and III)

- Construction Materials Testing Services

- Non-destructive Testing for Steel, Polymers, and Concrete Structures

- For more information about our services, please contact Qualitest Canada.

For more information or a quote, email us at admin@qualitests.com today.