Forcemain Pipe Inspection Services in Canada

Qualitest provides Forcemain Pipe Inspection Services in Canada wide. There are many good inspection companies provides the Foremain Pipe Inspection services in Canada. Qualitest is one of them and provides the top notch inspection and Non-Destructive Testing Services (NDT) including Borescope, Pipeline robotic crawler inspection, Visual Testing, Ultrasonic Testing, Magnetic Particle Testing, Liquid Penetrant Testing, Eddy Current Testing, PMI / OES examination, and other related tests. Qualitest provides the inspection and NDE / NDT services throughout Canada including Toronto, Mississauga, Hamilton, Sarnia, Milton, St. Catharines, Ottawa, Brampton, London, Markham, Vaughan, Kitchener, Windsor, Vancouver, Surrey, Langley, Richmond, Delta, Burnaby, Victoria, Kitimat, Dawson Creek, Kelowna, Kamloops, Edmonton, Calgary, Red Deer, Peace River, Grande Prairie, Fort McMurray, Regina and Saskatoon.

With a team of highly skilled technicians and state-of-the-art equipment, we specialize in providing top-notch force main pipe inspection services to ensure the integrity and efficiency of your wastewater infrastructure.

What are Forcemain Pipes?

Forcemain pipes are critical components of wastewater collection systems that transport sewage from pumping stations to treatment plants. As these pipes are pressurized, any defects or deterioration can lead to costly leaks, disruptions, and potential environmental hazards. Regular inspection and maintenance are essential to prevent emergencies and extend the lifespan of your force main system.

Our Services

Advanced CCTV Inspection: Our force main pipe inspection utilizes advanced Closed-Circuit Television (CCTV) technology to thoroughly assess the condition of your pipes from the inside. This non-intrusive method allows us to detect cracks, corrosion, blockages, and other issues without the need for excavation.

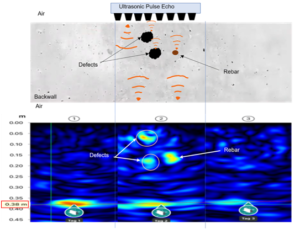

Ultrasonic Thickness Measurement: We employ ultrasonic technology to measure the wall thickness of your force main pipes accurately. This assessment helps identify areas of corrosion and potential weak points that require attention.

Leak Detection: Our skilled technicians use cutting-edge leak detection methods to pinpoint and assess leaks along the force main system. Early detection and repair can prevent further damage and mitigate the risk of contamination.

Deflection and Alignment Analysis: We conduct deflection and alignment analysis to identify any misaligned or sagging sections of the force main pipes, which could lead to flow restrictions and reduced efficiency.

Comprehensive Reporting: After each inspection, we provide detailed and easy-to-understand reports, complete with visual evidence from CCTV footage and ultrasonic measurements. Our recommendations and insights will help you make informed decisions about maintenance and repairs.

Why Choose Us?

Expertise and Experience: Our team of professionals has extensive experience in force main pipe inspection. They are equipped with the knowledge and skills to handle various inspection challenges.

Cutting-Edge Technology: We invest in advanced CCTV and ultrasonic equipment, ensuring accurate and efficient inspections with minimal disruption to your operations.

Safety and Compliance: Our procedures adhere to industry standards and safety protocols, prioritizing the protection of the environment and your infrastructure.

Timely and Cost-Effective Solutions: We understand the value of your time and resources. Our prompt service and proactive approach can save you from expensive emergency repairs.

Client-Centric Approach: We value our clients and prioritize your satisfaction. Our team is always ready to address your inquiries and tailor our services to meet your specific needs.

Conclusion

We are committed to helping you maintain a reliable and efficient wastewater infrastructure. With our expertise in force main pipe inspection, advanced technologies, and customer-centric approach, you can trust us to deliver accurate assessments and actionable insights. Contact us today, and let’s ensure the integrity and longevity of your force main pipe system together

Ensure the reliability and longevity of your force main pipe system with our professional inspection services. Contact us today to discuss your force main pipe inspection requirements in the Toronto area. Our dedicated team is here to assist you and provide the highest quality inspection solutions.

Contact us admin@qualitests.com today to get a quote.