Ultrasonic Pulse Echo (UPE) technology for Concrete structures

Qualitest Canada utilizes Ultrasonic Pulse Echo (UPE) technology to determine the integrity of all types of Concrete structures including Silo, MSC wall, Dams, Floors, tanks etc through its highly qualified Engineers and Inspectors. Qualitest Inspectors perform this Ultrasonic Pulse Echo Scanning services throughout Canada including Toronto, Mississauga, Hamilton, Sarnia, Milton, St. Catharines, Ottawa, Brampton, London, Markham, Vaughan, Kitchener, Windsor, Vancouver, Surrey, Langley, Richmond, Delta, Burnaby, Victoria, Kitimat, Dawson Creek, Kelowna, Kamloops, Edmonton, Calgary, Red Deer, Peace River, Grande Prairie, Fort McMurray, Regina and Saskatoon.

The damage and collapse caused by structural defects can be severe. Qualitest can help you test Concrete, rocks, composites, ceramics, wood, and refractory materials using State of the Art Ultrasonic Pulse Echo (UPE) technology to determine their strength and uniformity. Our clients include federal and provincial government, contractors, developers, consultants, and owners.

Ultrasonic Pulse Echo (UPE) technology can help identify some of key structural features of the concrete silos. For example, many the design documents are often lost or poorly maintained for some of the older concrete silos. Rebar spacing, and rebar size information can help structural engineers in evaluating the load bearing capacity of the silo structure. Structural flaws cause severe damage and collapse.

Ultrasonic Pulse Echo (UPE) is an advanced imaging technique used to detect defects in concrete structures. Ultrasonic testing provides information on the strength and quality of concrete Silos, and it can be used to determine voids, honeycombs, delaminations, pipes, cracks, and defects within the Silo structure. The ultrasonic pulse-echo (UPE) technology extends ultrasonic pulse velocity (UPV) applications to objects where access is limited to a single side. Qualitest uses the PD8050 for UPE testing, the World’s Lightest Wireless Ultrasonic Imaging System with Augmented Reality and Artificial Intelligence Capabilities.

Ultrasonic Pulse Echo can be used to find-out the..

- Location of subsurface defects of concrete such as flaws, cracks, honeycombing, and poor patches.

- Measurement of thickness of concrete elements

- Determination of concrete pulse velocity for homogeneity and strength estimation

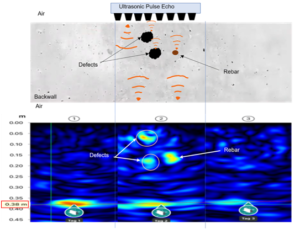

Figure 1: UPE scan performed on a concrete wall (cross section shown) containing a rebar and two defects. UPE scans gave a clear indication of thickness at 0.38 m.

Applications of Ultrasonic Pulse Echo include:

- Thickness measurement

- Strength evaluation

- Cracks and defect assessment – including Voids, honeycombs, and delamination

- Rebar, pipes &conduit localization

Advantages of UPE:

- Portable instrument allows for in-situ assessment

- Single side access is enough

- No couplant necessary

- No saturation with water needed

- Instant reading and quicker analysis

Contact us admin@qualitests.com today to get a quote.

- ON: 2711 Rena Rd, Mississauga, ON L4T 3K1, Canada, (647) 464-9480

- AB: 702 – 23rd Ave Nisku, AB, T9E 7Y6, Canada, (780) 851-2020

- AB: 320A – 65 Ave SE, Calgary, AB T2H 0R8, Canada, (587) 747-3787

- BC: 112, 13085 115Ave, Surrey, BC V3R 0C3, Canada, (778) 381-7376